W. Edwards Deming

Dr. William Edwards Deming (October 14, 1900 – December 20, 1993) was an engineer, statistician, professor, author, lecturer, and management consultant He helped develop the sampling techniques still used by the U.S. Department of the Census and the Bureau of Labor Statistics.

Deming championed the work of Walter Shewhart, including statistical process control, operational definitions, and what Deming called the “Shewhart Cycle” which had evolved into Plan-Do-Study-Act (PDSA). This was in response to the growing popularity of Plan-Do-Check-Act (PDCA), which Deming viewed as tampering with the meaning of Shewhart’s original work.

Deming was asked to go to Japan after World War II to help with the Japanese census, and later to improve radio manufacturing. Japanese business leaders knew about his abilities, and asked him to teach them about quality improvements. He taught numerous workshops to JUSE and other Japanese companies starting in 1950. He taught them statistical sampling and quality control techniques like SPC. But more importantly, he taught them about cooperation, optimization using systems thinking, and his 14 management points. This lead to his System of Profound Knowledge (SoPK).

He made a significant contribution to Japan’s reputation for innovative, high-quality products after World War II. He is regarded as having had more impact on Japanese manufacturing and business than any other individual not of Japanese heritage. He was honored in Japan in 1951 with the establishment of the Deming Prize.

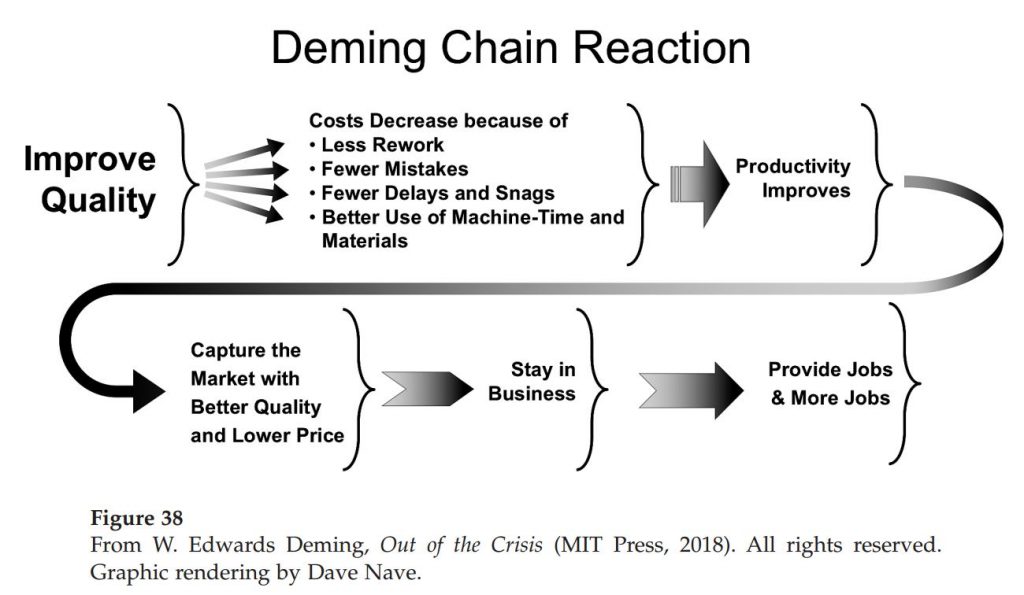

He also developed the Deming Chain Reaction, to show why improving quality is key to achieving business success and increasing the number of jobs to society.

To respond to the increased competition from Japan, the US developed numerous quality improvement programs, such as Total Quality Management (TQM), Business Process Re-engineering (BPR), Management by Objectives (MBO), and Six Sigma. However, they focused too often on the technical quality tools, but did not address the more difficult and important aspects: systems thinking and management principles.

Influences

Influenced

- Japanese Union of Scientists and Engineers (JUSE)

- Donald Wheeler

- Kaoru Ishikawa

- Ken Miller

- Boeing

- Bill Latzko

Links

- The W. Edwards Deming Institute

- Honoring Dr. William Edwards Deming

- Wikipedia

- Foundation and History of the PDSA Cycle – Ronald Moen

Books

Videos

On June 24, 1980, Americans widely viewed a NBC documentary called “If Japan Can… Why Can’t We.” The program, part of NBC’s White Paper series, prominently featured Dr. W. Edwards Deming. This compelling documentary introduced Dr. Deming to Americans. For the first time, they learned of the then 80-year old American who was widely credited with the Japanese industrial resurgence after WWII.

Dr. Deming discusses his 14 Points for Management in the video below. Read the full excerpt

Dr. Deming used the Red Bead Experiment to clearly and dramatically illustrate several points about poor management practices. This includes the fallacy of rating people and ranking them in order of performance for next year, based on previous performance. It uses statistical theory to show that even though a “willing worker” wants to do a good job, their success is directly tied to and limited by the nature of the system they are working within. Real and sustainable improvement on the part of the willing worker is achieved only when management is able to improve the system.

Additional Resources

- William Edwards Deming: The Father of Quality Management– creativesafetysupply.com

- The History of Six Sigma– lean-news.com

- Deming’s Contribution to Japan and Continual Improvement– blog.creativesafetysupply.com

- What is Lean manufacturing?– iecieeechallenge.org

- Implementing Six Sigma– hiplogic.com

- Lean and Mean: Making Time to Achieve It– 5snews.com

- Total Quality Management And Kaizen Principles In Lean Management– kaizen-news.com

- The Concepts of Kaizen– creativesafetypublishing.com